Manufacturing Process

At Sunset Sleepers, our concrete sleeper manufacturing process ensures precision, durability, and high-quality concrete sleepers for retaining wall structures.

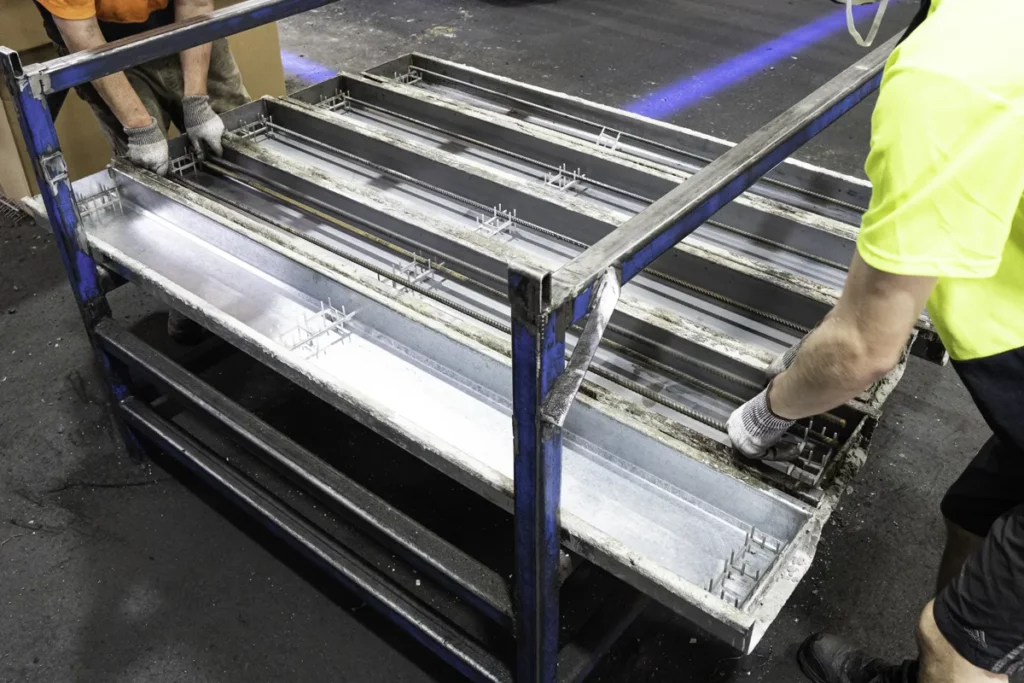

Step 1. Mould Creation

The foundation of a superior concrete sleeper begins with a high-quality mould.

We manufacture all of our our concrete sleeper moulds in-house using specially selected steel.

The steel is cut, bent, and welded with a slight taper (5-7mm at the ends from face to back of sleeper at the ends) to allow for easy de-molding without damaging the sleepers.

Step 2. Mould Cleaning

After each production cycle, every concrete sleeper mould undergoes a thorough cleaning process.

Depending on the condition of the mould, cleaning may involve:

- Simple vacuuming and wiping with a cloth.

- Using steel wool for moderate dirt.

- A steel brush is employed for heavier debris.

Step 3. Application of Release Agent

A special release agent spray is applied to the clean concrete sleeper mould to ensure the concrete sleeper does not stick during the de-molding process.

A thin, even coat of the agent is applied, similar to greasing a baking tray, and is left to settle.

Step 4. Reinforcement Placement

All our concrete sleepers are reinforced using 2x N12 REO Bars as Standard to for superior strength, durability and resistance to cracking.

Depending on the sleeper width and length, 3x N12 reinforcement bars are used, although we can custom manufacture all of our concrete sleeper sizes in 3x N12 if required by the customer..

Purpose-built reinforcement bar holders (or “chairs”) are used to secure the bars in the correct position.

Step 5. Concrete Pouring and Vibrating

The concrete sleeper moulds are then filled with a specially engineered Boral® concrete mix rated at a minimum of 40 MPa.

The concrete sleeper mould are then vibrated to eliminate any air bubbles and ensure a dense, uniform concrete sleeper.

For concrete sleepers requiring custom colour, oxide pigments are added to the concrete mix prior to pouring to achieve a consistent, vibrant finish.